Conveyor belts are ubiquitous in various industries, playing a crucial role in streamlining operations and enhancing productivity. However, despite their numerous benefits, conveyor belts can pose significant hazards if improperly managed. Understanding these risks is imperative for creating a safer work environment and reducing the likelihood of accidents.

Let’s look at four reasons conveyor belts can be hazardous and what measures you can take to mitigate these risks.

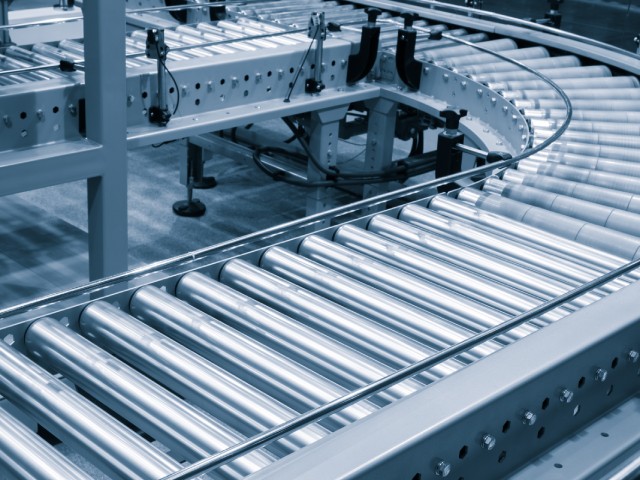

Conveyor belts have many moving parts, including motors, rollers, and pulleys. These mechanical components can cause severe injuries if they come in contact with workers’ hands or clothing. Additionally, loose clothing or jewelry can get caught in the belt and pull people into the machinery, resulting in serious injuries or even death.

To prevent such accidents, conveyor belts must receive regular inspections and maintenance to ensure all moving parts are functioning correctly. Workers should also receive adequate training on how to operate and work around conveyor belts safely.

In industries where conveyor belts transport chemicals or other hazardous materials, a risk of exposure to harmful substances exists. If these substances leak or spill from the belt, they can cause skin irritation, respiratory problems, and even chemical burns.

To mitigate this risk, it’s crucial to properly label and store chemicals before transporting them on conveyor belts. Regular cleaning and maintenance of the belts should also occur to prevent leaks or spills. Workers should wear appropriate personal protective equipment (PPE) when handling hazardous materials as well.

Conveyor belts can quickly spread a fire due to inadequate maintenance or if flammable materials come in contact with them. The belt’s high-speed movement can create friction and heat around materials, leading to combustion.

Regular inspections and maintenance are necessary to reduce the risk of conveyor belt fires. You should also train all workers to identify potential fire hazards and respond to a fire.

Manual handling of heavy objects on conveyor belts can strain and injure workers’ backs, shoulders, and arms. Standing for prolonged periods while working with conveyor belts can also lead to musculoskeletal disorders.

To prevent these ergonomic hazards, you should provide proper training on safe lifting techniques to employees. Employers should also consider implementing automation or using lifting aids to reduce the physical strain on workers.

By understanding these four potential hazards of conveyor belts and taking proactive measures to mitigate them, employers can create a safer workplace for their employees. Following a proper conveyor belt safety guide and conducting regular risk assessments can go a long way in preventing accidents and ensuring workers’ well-being. Additionally, promoting a safety culture where employees can easily report any potential hazards can further improve workplace safety. Remember that prevention is always better than cure when it comes to avoiding conveyor belt accidents.

24World Media does not take any responsibility of the information you see on this page. The content this page contains is from independent third-party content provider. If you have any concerns regarding the content, please free to write us here: contact@24worldmedia.com